COVID-19 Ventilation

As defined by the Health & Safety Executive (HSE) website, the law states that “employers must make sure there’s an adequate supply of fresh air (ventilation) in enclosed areas of the workplace”. Following the COVID-19 pandemic, this of course is now even more important. Adequate ventilation reduces how much virus is in the air. It helps reduce the risk from “aerosol” transmission. Aerosol transmission can happen when someone breathes in small particles in the air (aerosols) after a person with the virus has been in the same enclosed area.

The risk from aerosols is greater in areas that are poorly ventilated.

You can do this by using:

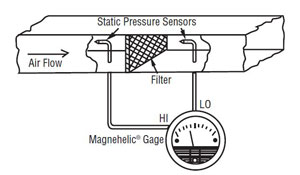

- natural ventilation – fresh air comes in through open windows, doors or air vents. This is also known as ‘passive airflow’, or

- mechanical ventilation – fans and ducts bring in fresh air from outside

(The above links will take you directly to the HSE website).

From either method above though, it is important to quantify the performance of your ventilation, be that natural or mechanical. An HSE recognised method is via CO2 detectors. Fluidic have a long history of supplying Vaisala CO2 detectors such as the GMW90 Series. This wall mountable detector also has options for RH&T monitoring to ensure your office is operating at the most comfortable and efficient conditions. A local display is accompanied by red/amber/green warning LEDs for quick visualisation of office conditions. A 4-20mA signal can also be brought back and incorporated into your office BMS system where appropriate.

Video by the HSE on Ventilation and the use of CO2 detectors

Along with the links above, see HERE for more information directly from the HSE website.

Within our own Glasgow office, we are currently using a GMW86P sensor, connected to our Hanwell EMS datalogging system. This gives real-time logging of current CO2 levels, with email alarm alerts should CO2 levels rise beyond an internally set threshold. This system gives 24/7 monitoring, so we can also measure CO2 levels when the office is unmanned, useful as a reference level vs a full office. A remote log in demonstration is available if you were interested in this system – please call the Glasgow office on 0141 641 5920 to arrange.

Some photos of our setup can be seen below:

The above shows the Vaisala GMW86P which provides a continuous 4-20mA output. The 4-20mA is collected by a Hanwell RL4809 and information updated to our Hanwell EMS system every 15 mins. Incidentally, to the left of the RL4809, note we have an RL4114 RH&T transmitter to monitor the general comfort levels for our team. This is a 3.6V AA battery powered device, with battery life expected <2years in normal service. Fluidic offer annual calibrations on most Hanwell transmitters and would generally change the battery as part of this.

Above shows a screenshot of yesterday (noting this post was created 14/12/21). We have a high level alarm at 1,000ppm in line with ASHRAE typical standards and a High High alarm at 1300ppm – set as a failsafe for our own peace of mind. Although our office is showing CO2 levels well within these levels, it is interesting to note that there is a clear rise in CO2 levels as the team start to come in the office at about 8.30am, dropping again just after 5pm.

For help with any ventilation measurement application, please call either office – Glasgow (0141 641 5920) or Warrington (01925 572401).