One of the most common measurements taken by instrumentation is pressure, particularly differential pressure. So, what is differential pressure and how is it measured?

What is Differential Pressure (DP)?

Differential pressure is, quite simply, the difference in pressure measured between two points. Filtration is a common application where pressure drop across a filter (i.e. the pressure difference between upstream and downstream of the filter) is indicative of filter condition. A blocked filter, or one nearing saturation, will cause a large pressure drop and require the associated pump/fan to work much harder. This is easily monitored by DP, allowing an economical filter change maintenance routine. Additionally, it can be noted that a very low differential pressure could identify a burst filter. (The Dwyer Photohelic A3000 Switchgauge and Dwyer Photohelic 3000MR Switchgauge both include a gauge measurement display and adjustable high and low DP switch outputs for such practice).

Other common applications include cleanroom monitoring (to ensure rooms are maintained at positive or vacuum pressure as required, often in a cascade environment). In hydrostatic level monitoring, we often use differential pressure to compensate for any inherent pressure in the tank. See the Honeywell STF800 SMARTLINE Hydrostatic Level Transmitters for more details of this application.

Particularly in air or gas applications, differential pressure can be very low – often measured in Pascals. One Pascal (1Pa) is the equivalent of 1/100,000 bar. It is essential to ensure that the correct type of differential pressure instrument is selected per application.

How do we select the correct differential pressure instrument?

This will depend on a number of factors, but the measurement principle remains similar regardless.

As mentioned earlier, differential pressure is measured between two points. This may be two pressurised areas or one pressurised area with the other open to atmosphere. The measurement will be taken through the instrument, be that a gauge, switch or transmitter.

In all DP instruments, each pressure input will feed either side of a measurement diaphragm. The diaphragm will flex in the direction of +ve differential pressure. The extent of this positive deflection will drive the measurement sensor (often a piezoelectric sensor, or in the case of the Dwyer Magnehelic Differential Pressure Gauge via a magnetically driven helix), to a conditioned output, trip or gauge display.

It can be seen that diaphragm material selection is extremely important. When selecting the type of instrument required it is essential to know the ballpark range of pressure the instrument will be dealing with, as well as the medium that it will encounter. Diaphragms come in various material types to handle the varying ranges of these requirements. The commonly specified 316SS diaphragm will not typically suit small, pascal measurements such as cleanroom or air HEPA filter monitoring applications. Our range of transmitters from Micatrone along with Dwyer’s previously mentioned Magnehelic and Photohelic options utilise large rubber diaphragms which are responsive to small pressure changes. Dwyer have recently released a new 0-30Pa range within the Magnehelic allowing higher accuracy than ever before in such applications.

Dwyer Magnehelic Product Overview Video

DP vs two separate pressure measurements?…

In theory, two separate pressure transmitters could be used to generate a DP measurement within the control system itself. For example, a liquid line may be running at 3bar. A filter with a normal operating pressure drop of 100mbar could be considered for change at, e.g. 200mbar (manufacturers will normally recommend specific values). It could be argued that a 0-5bar transmitter/gauge may be fitted either side of the filter. In clean conditions upstream will measure 3bar, downstream 2.9bar, giving a differential of expected 100mbar. HOWEVER, give consideration to the uncertainty of measurement of each device, which is typically taken as a percentage of full scale. For a +/- 1%fs instrument, a 0-5barg pressure transmitter will have an uncertainty of 50mbar. Doubling this (as there are two transmitters), the total DP measurement reading could be argued as 100mbar +/- 100mbar!! Using a differential pressure transmitter of range e.g. 0-500mbar DP and the same +/-1%fs, the same measurement would be 100mbar +/- 3mbar – a much more reasonable working tolerance.

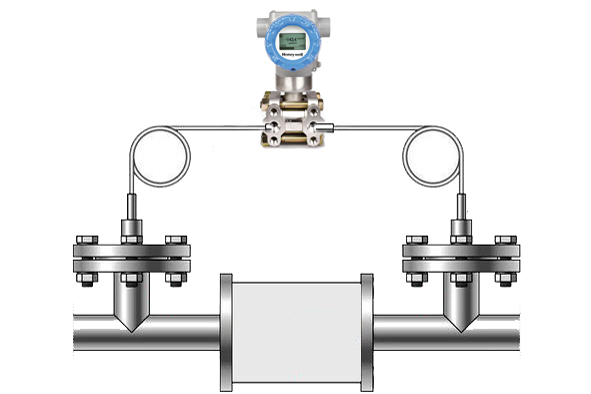

The very crude “knock up” schematic above shows how a Honeywell DP transmitter may be fitted across a liquid filter bank for DP measurement.

Many manufacturers offer “electronic DP” using two gauge pressure transmitters. There can be a lot of benefits in this design, but always give consideration to each specific application and the pressures etc under scrutiny. Fluidic have engineers on hand to help with instrument selection.

Please call either office for more information (Glasgow 0141 641 5920, Warrington 01925 572401)